PROACTIVE HEALTHCARE MAINTENANCE MANAGEMENT

Our unique Healthcare Maintenance Management program uses proactive Contract mechanisms to lock in performance guarantees for critical equipment with the OEM’s and vendors. The focus is typically on rotating equipment historically known to be one of the primary causes of lost production / power generation. Our strategy is to prepare a tailored framework contract which spreads responsibility, risk and reward to the Vendor supplying needed specialized technology and skilled services. This type of “Assurance Policy” can be extended to control systems, electrical systems or equipment experiencing reduced performance or high rates of failure which is a win-win approach for all business entities.

Technical Services Offered by AIMS

- Coverage for scheduled and un-scheduled maintenance on critical existing and new heavy equipment packages typically applied to rotating equipment with mid to high operational rates of failure

- Installation and commissioning management of new heavy equipment packages

- Total coverage and liability through provision of AIMS Healthcare contracting methodology using specialist Vendors to address heavy equipment operational failures

- Transfer of risk, responsibility and accountability

Reasons for Sourcing Healthcare Management from AIMS

- AIMS Healthcare contracting focuses on the OEM / Vendors ability to efficiently support proprietary technology (eg. DLE for gas turbines), hardware and software (PLC ladder logic) of operating equipment

- Provision of OEM certified service technicians (FSR's). The right experienced discipline techs are sourced through AIMS to ensure effective responsiveness (from planned maintenance to urgent requirements)

- Genuine OEM equivalent spare parts are supplied as part of a framework agreement where discounts can be negotiated (up to 10% for the term of contract can be considered)

- Privileged access to fleet of lease-pool equipment. A 14 day ex-works guarantee to supply replacement core engines for gas turbines is a typical commitment

- Direct connection to world wide service networks, repair and overhaul facilities

- Diagnostic capability for core engine and package data through Electronic Data Exchange Network

- Services complement warranty on new packages

- AIMS Healthcare Management is a methodology to detract from operational fire fighting caused by unplanned downtime occurrences experienced with complex production equipment

Proposed Healthcare Contract Framework

- Covers planned maintenance and breakdown maintenance for existing packages and new packages over a 10 year duration

- All spare parts including replacement core equipment (eg. gas turbines and power turbines) in the event of catastrophic breakdown (Lease Pool access)

- All manpower for planned and breakdown maintenance

- A dedicated site service engineer during production (as required depending on equipment to be managed)

- Guaranteed response times and 4 weeks turnaround time for catastrophic failures (typical as part of Vendors health care coverage and liability)

- Budgeted spend over ten years utilizing framework negotiated pricing at present value

- AIMS will fully coordinate and manage the scope

Provision of Manpower Contract

- Repair and Maintenance Services - Supply of specialist personnel - planned or required

- Installation, Pre-Commissioning, Commissioning and Start-up services for selected heavy equipment (eg. gas turbines)

- PLC ladder logic programming (control of software is managed by AIMS)

- Inclusive of travel and accommodations

- Emergency call out service and help desk availability

Provision of Materials Contract

- Provision of all equipment and materials within agreed framework scope for the Repair and Maintenance Services of selected heavy equipment

- On-site stock holding

- Privileged access to fleet of lease-pool equipment. A 14 day ex-works guarantee to supply replacement core engines for gas turbines is a typical commitment (from lease pool or available from manufacturers production)

AIMS Interface Lead

- AIMS will construct the detailed SoW, assemble and negotiate the contract

- AIMS will coordinate directly with Asset Operations to secure condition monitoring / field data, interrogate the data and connect with respective OEM / Vendor specialists to recommend corrective works or upgrades within the terms of the contract

- AIMS will manage and control all software interfaces, PLC ladder logic changes

- AIMS will ensure compliance with provisions to the framework agreement

- AIMS will manage performance data and materials reconciliation

- AIMS will develop the financial model, accrual and controls of the contract

AIMS goal is to help customers maximize production by connecting the right resources to effectively improve uptime and availability results from critical equipment. Click here to see how we get there for a 6 turbine fleet base case.

Data collection and analysis examples:

Eg. Gas Turbine monitoring of parameters (monthly summary)

Eg. Bearing Vibration Monitoring (Drive End and Non-Drive End): Trend projected through upper vibration limit.

Alerts decay in bearing system requiring corrective maintenance.

AIMS Provision For Healthcare Maintenance Planning and the E. Systems Platform

To ensure optimum health, safety, environmental effectiveness and minimum business risk within Operations, it is essential that the correct level of preventative maintenance and corrective maintenance is managed and executed. AIMS Technical Integrity Management Program provides the platform for managing maintenance.

AIMS recommended strategy is to divide the required level of maintenance into three groups:

1. Operations and Maintenance personnel develop general maintenance procedures and conduct front-line maintenance with support provided by logistics and procurement

2. The Asset Maintenance Service Contractor (MSC) executes volume routine maintenance procedures (preventative maintenance tasks and spare parts allocation)

3. Utilize Specialist Maintenance Vendors and Service Contractors in completing unique maintenance works requiring specialist skills or proprietary technology (eg. PLC software logic upgrades). This type of maintenance is conducted under the AIMS Healthcare Contract process for complex systems assurance integrity during the life cycle of the operation.

Process Flow

AIMS prepares the strategy for identification and type of vendor contract required based on the decisions to be made and taking into account key parameters and current expertise within the base crew of the Operation. The starting point is to identify key items of process equipment, associated maintenance requirements and the criticality of the equipment within the designated process design which is then correlated to the execution capability of the base crew.

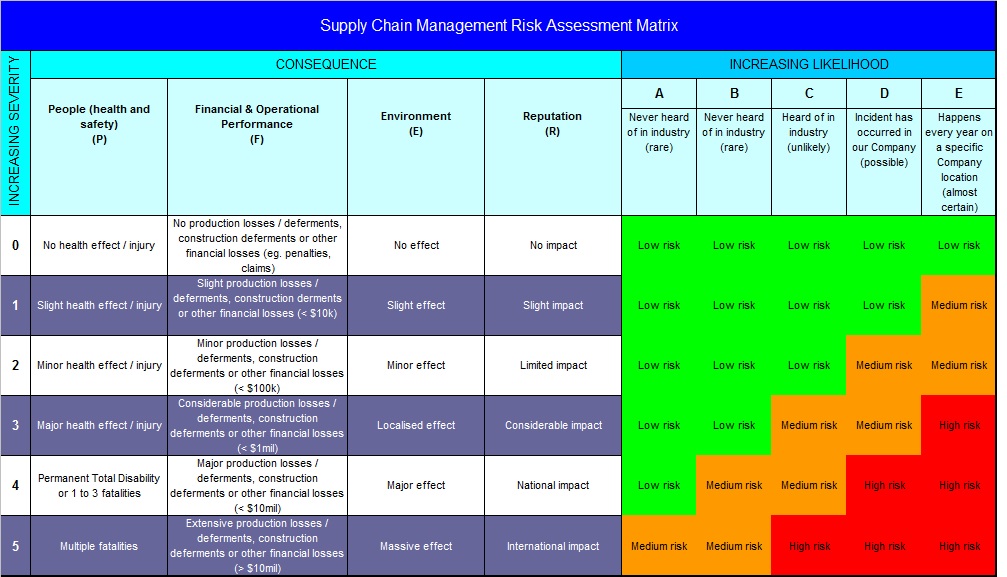

The next process step is to identify the risk to the Operator of the equipment being unavailable or failing in service. This is accomplished using the Supply Chain Management Risk Assessment Matrix which measures consequence in regards to people, health and safety, financial and operational performance, environment and reputation to Company against increasing levels of likelihood.

Owing to patent protection, proprietary rights or unique software / tooling needed to maintain the equipment, the OEM service is identified and correlated to the capability of the asset base crews.

In the implementation of Maintenance Vendor Contracts, there will primarily be four “Insurance” types of Contracts utilised:

-

Specialist Maintenance Contract – local supply of discipline maintenance personnel to site or at local workshops.

-

Long Term OEM Service Contracts under the AIMS Healthcare program – for equipment assessed to be medium or high risk where input is required from the OEM. AIMS Healthcare Contracts are fundamental for Technical Integrity and Production Up-time. Note, consideration is made to deploying an OEM Resident Engineer on site.

-

Call-off OEM Service Contract – the total scope of specialist maintenance required is determined based on the current competency of the asset base crew.

-

Ad-Hoc OEM Contracts – the asset base crew is expected to execute all routing maintenance works, however, a call-off may be required for emergency or unique failure occurrences where the OEM Vendor is required to oversee the work or supply specialist materials / tooling. AIMS negotiates terms for suitable response times without premium rates.

AIMS Maintenance and E. Systems Module

The electronic Maintenance Management System (CMMS) aligned with AIMS will provide a framework for Maintenance Management of all Assets, safeguarding Technical Integrity, optimizing Reliability, Availability and Cost Control. The intent is to Safeguard Technical Integrity to prevent, detect, control or mitigate any hazardous condition with the potential to cause a major accident jeopardizing Company HSE objectives.

AIMS Preventative Maintenance Program: AIMS can play an inherent part in building the Company E. Systems Module applied to Preventative Maintenance Works. As part of the AIMS Preventative Maintenance Program, AIMS will populate and build the PM work packs, timelines, and spare parts requirements for the CMMS Module. All associated reporting is provided by AIMS.

AIMS Predictive Maintenance Program: A set of acceptance criteria is specified for the selected condition monitoring and performance parameters allowing early identification of deteriorating condition (eg. vibration trend monitoring for rotating equipment) and preparation of equipment re-Commissioning Programs, including functional and performance test procedures. AIMS tools and skilled engineers will provide analytics to trend the condition. For the case of improving conditions, AIMS Predictive Maintenance will trend to reduce unnecessary maintenance (part of the AIMS loss prevention protocol to reduce waste).

AIMS Reliability Improvement Methods: Our highly skilled and experienced Engineers will engage in equipment trouble shooting, failure analysis, review of root causes, operating envelope, preparation of conceptual design proposals and recommendations for Reliability Improvement.

AIMS Inventory Control: AIMS as the MSC will prepare the e-SPIR’s for capital, insurance, operational and front line spares (within the AIMS OEM Healthcare Contracts) with inventory min / max settings based on OEM recommendations and condition. AIMS Procured Equipment Management will provide Supply Chain Monitoring / Tracking, Rush Orders, and Supervision of off-site Refurbishment of parts and receipt inspections in concert with Company logistics and procurement. AIMS will prepare the routing daily, weekly and yearly work orders / job packs tying the spare parts requirements to the routing work orders. All spare parts requirements and work orders are uploaded into the CMMS MRP E. system aligned with AIMS.

AIMS Training is provided to transfer knowledge (addressing Nationalization priorities in particular) and ensure certification of base crews including annual certification of electrical personnel and test equipment, mechanical workshop PSV test bench and certification of safety appliances (life boats, rafts, etc.) all performed locally when practical.

AIMS Measurement of baseline performance indicators is essential, in order to identify reliability and efficiency improvements. Monitoring against the following Maintenance Performance Indicators is managed by AIMS Dashboard Analytics:

-

Equipment availability: Uptime versus Use Factor

AV = (Operation Time + Standby Time) / Time Interval

AV = MTBF / (MTBF + MTTR)

-

Equipment reliability: Time period the equipment could have been in Reliable Service

RE = (Time Interval – Breakdown Time) / Time Interval

-

Equipment utilization:

UF = Operating Time / Time Interval

-

MTBF and MTTR: Mean Time Between Failure and Mean Time To Repair

-

KPI’s: Turnaround time, repeat jobs, reliability, actual condition, logistics, % compliance

All maintenance campaigns and data control will be planned within the CMMS E.Systems Module aligned with AIMS. AIMS recommends to build the systems up front at the start of a Facility Development thus having the CMMS defined and implemented for a seamless start-up. Systems are regularly updated during the life cycle of the Facility.

With the objective to build a robust Maintenance program and strong diagnostic capabilities, AIMS prepares the OEM Healthcare and Call off Contracts (Electrical, Mechanical and Instrument) for identified Rotating Equipment, Safeguarding & Control Systems, and DCS Systems. As part of the Healthcare Contracts Management, AIMS ensures availability of OEM special tooling to complete repairs in-situ.

AIMS puts the Customer objectives first. Our business principles focus on: Loss prevention, Opex reduction KPI targets, responsible HSE culture, optimal utilization of equipment and materials including spare parts, extending the asset life cycle, plant integrity, maximizing nationalization by training and protecting Client reputation.